Submer Tech

Datacenter building blocks

We deliver engineered hardware solutions that power next-generation, liquid-cooled datacenters—driven by our global R&D and engineering expertise. Whether through standardized products or custom co-designed systems, we’re your trusted partner to build smarter, and scale faster.

Standarized products

Co-developed solutions

PRODUCTS

Datacenter-ready hardware

engineered for liquid-cooled environments.

At Submer, we engineer advanced solutions for the infrastructure and IT demands of modern liquid-cooled datacenters — that maximize performance, scalability and sustainability.

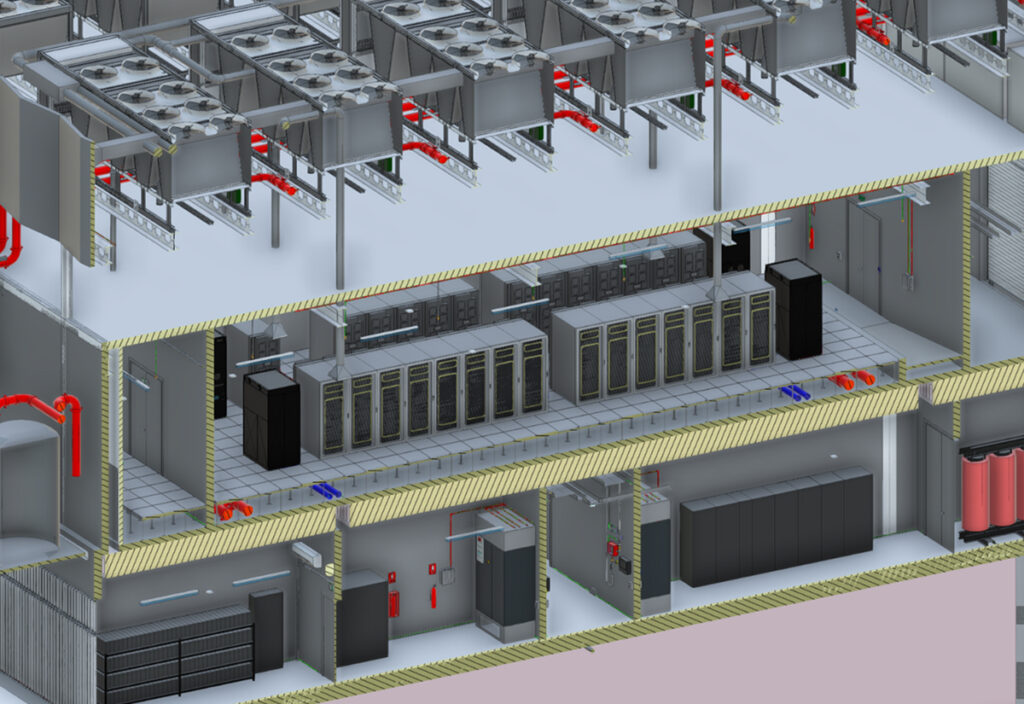

[1]

IT & Cooling

Our offering includes DLC systems developed through strategic partnerships, immersion cooling pods, and reference architectures.

[2]

Infrastructure

Our infrastructure solutions include modular power systems, dry coolers, robotics, and fast deployment modules.

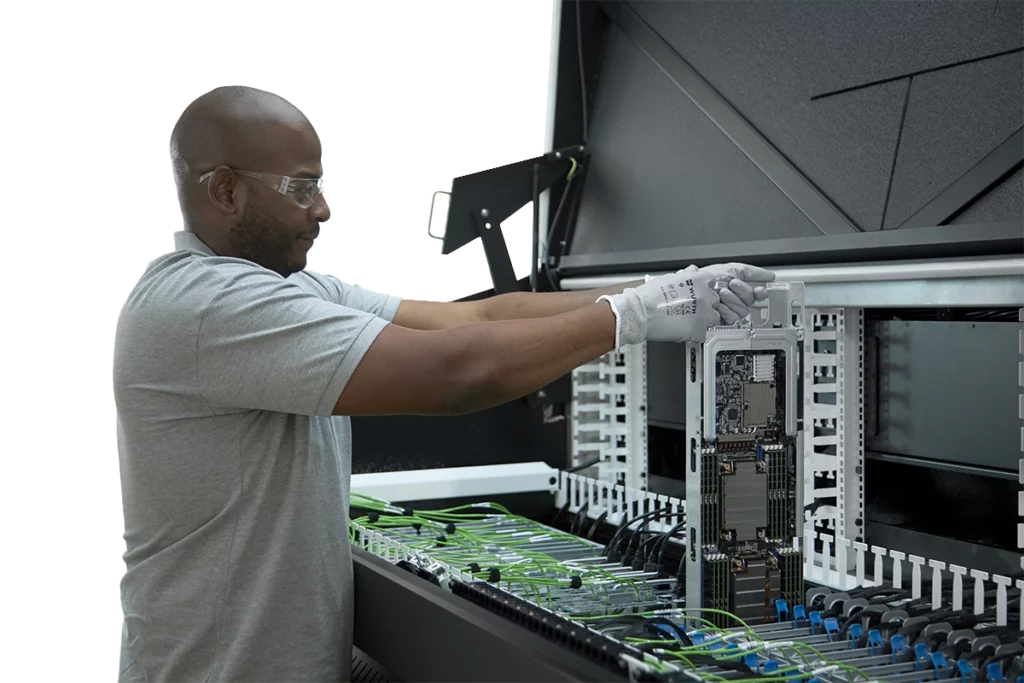

[3]

Operations

Purpose-built tools and systems to simplify maintenance and ensure daily operational efficiency in liquid-cooled environments.

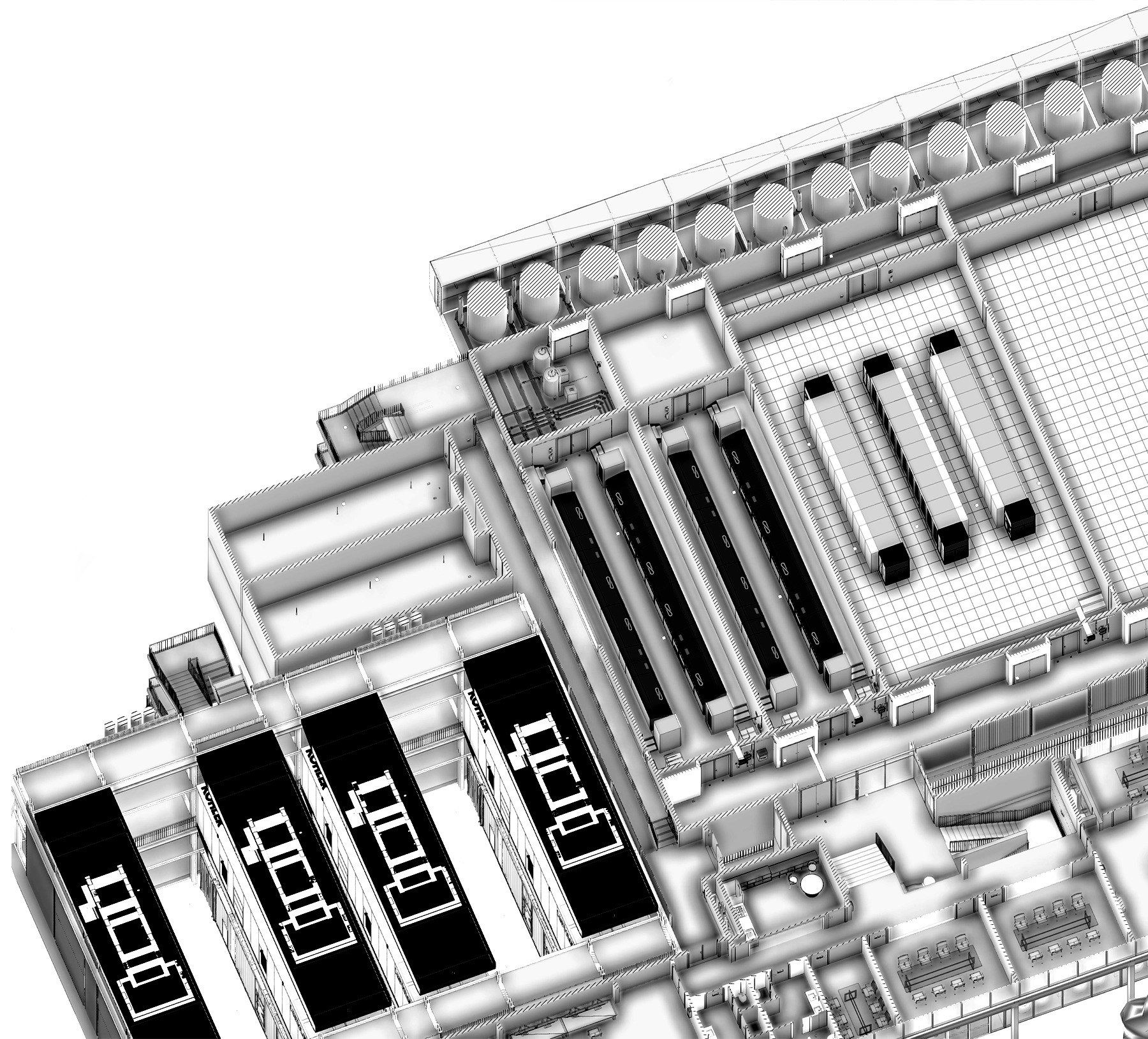

BUILDING BLOCKS

Hardware that delivers

infrastructure that scales

Access the core building blocks of the liquid-cooled datacenter, from IT and liquid cooling systems to modular power delivery and infrastructure modules—all designed for the highest performance and reliability.

Faster time-to-market

Pre-engineered modules enable rapid deployment, accelerating datacenter readiness and reducing project timelines.

Lower TCO

We design and manufacture solutions for deployment at scale by leveraging building our own supply chain.

Reduced Integration Risk

Submer is actively engaged in all aspects of the datacenter life cycle, from ideation to operations. This expertise is built into our products.

Scalable by Design

Standardized building blocks support seamless scaling from kilowatt to gigawatt deployments.

Global R&D and Support

Access to a worldwide innovation network speeds up product iteration, certification, and regional adaptation.

Reduced Integration Risk

Submer is actively engaged in all aspects of the datacenter life cycle, from ideation to operations. This expertise is built into our products.

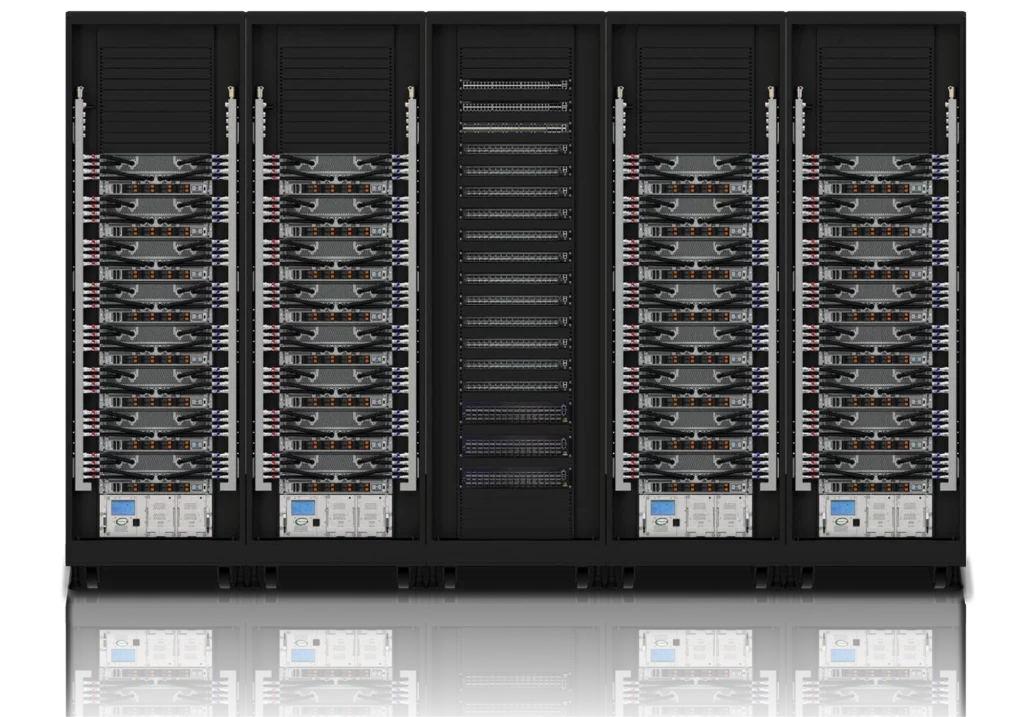

IT HARDWARE

Liquid cooling solutions

ready for deployment

At Submer Tech, we engineer advanced solutions for the infrastructure and IT demands of modern liquid-cooled datacenters — that maximize performance, scalability and sustainability.

Direct Liquid Cooling

Implementing the industry reference designs

- Bringing deployments and reference designs to the next level

- Minimizing the need for air cooling

- Decreasing environmental footprint

- Delivering the performance needed by current and future technologies

- Innovating in hybrid liquid cooling deployments

Immersion Cooling

Optimized for energy efficiency and climate resiliency

- Improves overall eficiency

- No vendor locking

- Climate resilency

- Optimizing industry reference design

- Free cooling

The easiest path to immersion cooling, the SmartPod EVO unlocks the potential of every square foot in your datacenter.

The SmartPod EXO offers extreme density and ensures your datacenter is climate-resilient.

The smartest solution at the edge, our datacenter-in-a-box solution delivers high density compute power anywhere.

Reference architectures

Fully integrated, pre-validated hardware systems

- Pre-certified compute platforms: engineered with top OEMs/ODMs to ensure optimal performance for any liquid-cooled application.

- Liquid cooling platforms: based on existing or adjusted manufacturer Reference Architectures

- Prefabricated MEP Modules: Skids for power and cooling systems to speed up on-site deployment.

- Modular Data Center Units: Containerized datacenters or pre-engineered pods for rapid deployment.

Liquid Cooling Accesories

Validated accesories for the liquid cooling ecosystem.