One of the most common questions we’re asked by end users looking to adopt immersion cooling is that of material compatibility. Many seem to have the perception that changing from air cooling to a dielectric fluid could potentially put their hardware at risk.

In this blog post, we’ll put your worries to rest by presenting both problem and solution for each of the four main elements of material compatibility in immersion cooling: alternatives for polyvinyl chloride (PVC) cables, replacing thermal pastes with solid Thermal Interface Materials (TIMs), and selecting the right seals and adhesives.

1. PVC Cables

Although polyvinyl chloride (PVC) cables work as intended while submerged in immersion fluids, their long-term compatibility is questionable.

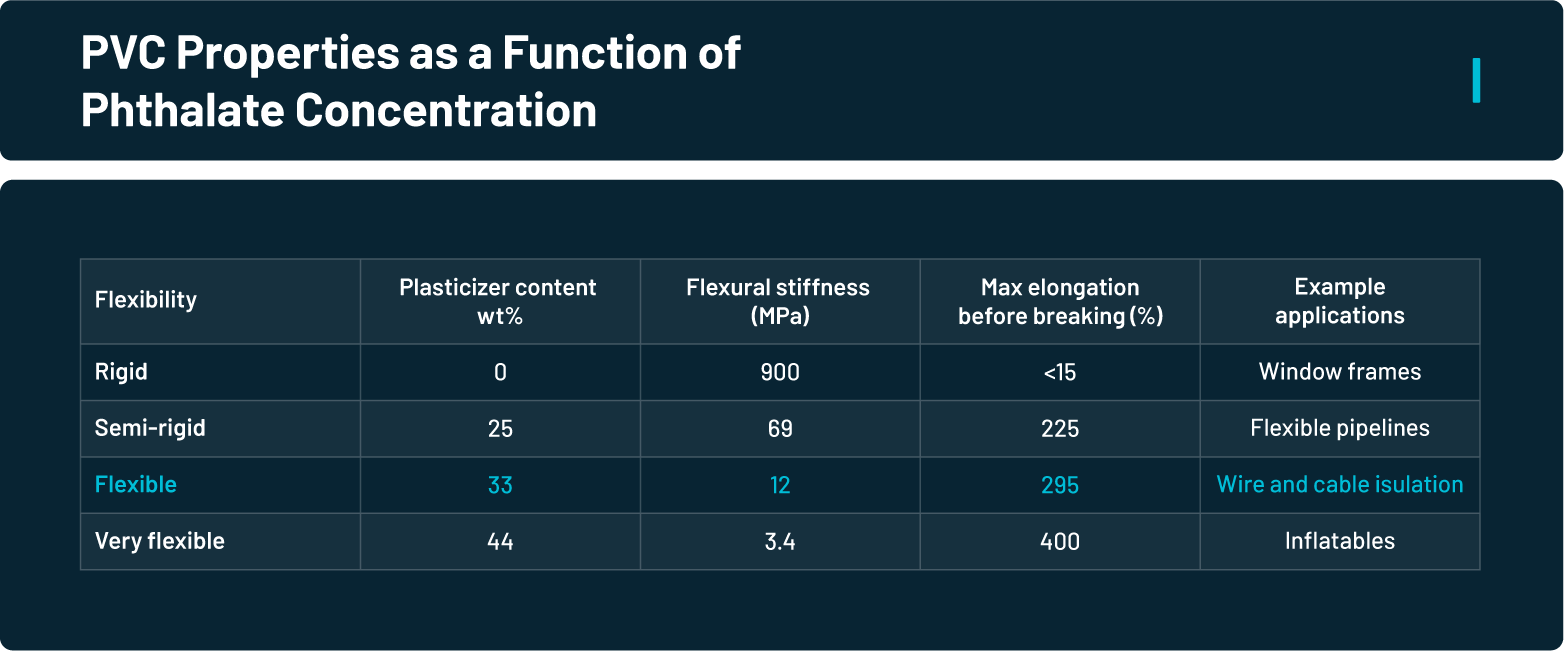

This issue arises due to plasticizers leaching onto the immersion fluid. Plasticizers are often added to polymers, such as plastics, to facilitate manufacturing or to attain the desired properties for a specific application. Plasticizers such as terephthalate and phthalate esters, which dissolve in hydrocarbon fluids, are commonly used in PVC manufacturing. The migration of these plasticizers out of their host plastics causes the loss of flexibility, embrittlement, and cracking.

The result? The outer sheath of the once-flexible PVC cable can end up breaking upon handling, exposing its inner contents. As well as presenting risks, peeling cable isn’t particularly pleasing to look at.

Introducing PUR

Thankfully, we have better alternatives than PVC. Cables with outer sheaths made of materials like polyurethane resin (PUR) do not show the stiffening and brittleness observed in PVC cables.

PUR are thermoplastic elastomers which combine the processing advantages of thermoplastics with the performance properties of elastomers – meaning there’s no need for plasticizer addition during manufacturing.

2. TIMs

Most Thermal Interface Materials (TIMs) are used to bridge the air gap between the chip and the heatsink to allow for efficient heat dissipation.

The majority of TIM found on air-cooled devices are made of some form of hydrocarbon “greases”. The grease matrix used to disperse the thermally conductive fillers, such as metal (silver and aluminium) and ceramic (boron nitride) particles, dissolves in contact with single-phase immersion fluids. This dissolution jeopardizes effective heat transfer from the CPUs to the fluid, resulting in a poor overall performance of the system in the long run.

Although small quantities of thermal grease dissolving won’t affect the cooling system, it’s true that the performance of the IT hardware may be compromised because of poor heat dissipation at the CPU level.

Enter Graphite & Indium Foil

Alternatives such as graphite pads and malleable metallic sheets, like indium foil, are solid TIM alternatives to effectively manage thermal transfer. These innovative solutions for the dissolving dilemma ensure steadfast heat transfer capabilities and safeguard sensitive components.

3. Seals and Gaskets

The compatibility of seals with single-phase immersion cooling fluids is a valid concern for industry stakeholders, especially since these seals are usually found in spots where tight control of fluids permeation/leakage is required.

Materials such as Ethylene-Propylene-diene monomer (EPDM), natural rubber, nitrile-butadiene rubber (NBR), and silicone seals demonstrate a tendency to swell considerably, compromising their sealing efficacy and potentially leading to fluid permeation or leakage.

Success with Viton®, FKM, and PTFE

Viton®, fluoroelastomers (FKM), and polytetrafluoroethylene (PTFE) seals remain resilient when exposed to immersion cooling fluids. These materials offer impeccable performance, withstanding high pressures and temperatures, and maintaining exceptional chemical resistance, which all adds up to a reliable and leak free environment.

4. Material Compatibility in Immersion Cooling: Adhesives

Immersion-cooled servers often sport small labels with sensitive information. An incompatible adhesive could lead to peeling and sinking.

Cyanoacrylate-Based Solutions

For paper labels adhered to flat surfaces, acrylate-based adhesives, such as cyanoacrylates, are the answer. They display remarkable compatibility, forming robust and durable bonds that ensure labels stay put.

Our Quest to Combat Challenges

In our pursuit to address the challenges associated with immersion cooling, we’ve discovered these aforementioned solutions such the adoption of PUR cables, solid TIMs for efficient thermal management, resilient seals, and cyanoacrylate-based adhesives.

By embracing immersion cooling and the application of innovative material compatibility solutions, we can collectively propel the datacenter industry toward enhanced reliability and sustainability. Let the cooling journey continue!