Immersion cooling a.k.a. liquid submersion cooling is the method of submerging computer components or full servers in a thermally, but not electrically, conductive liquid.

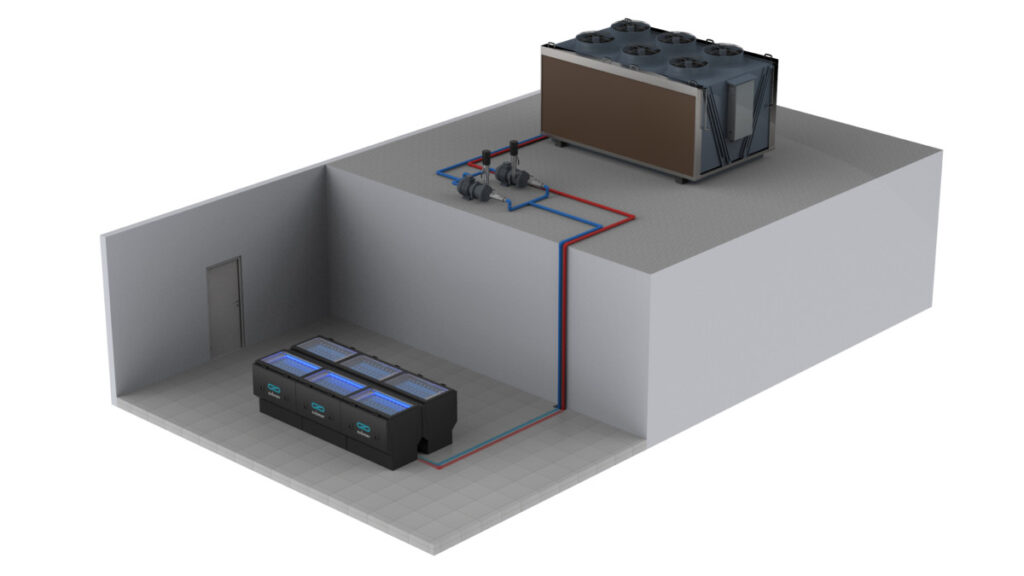

This innovative way of cooling IT hardware or servers doesn’t require fans and the heat exchange between the warm coolant and cool water circuit usually occurs through a heat exchanger i.e. a heater core or radiator.

Some extreme-density supercomputers, such as the Cray-2 and Cray T90, use large liquid-to-chilled heat exchangers for heat removal. In this case, the fluid used must have sufficiently low electrical conductivity so as not to interfere with the normal operation of the computer. If the fluid is somewhat electrically conductive, it may be necessary to insulate certain parts of components susceptible to electromagnetic interference, such as the CPU. For these reasons, dielectric fluid is preferred.

Is Immersion Cooling the Same as Water Cooling?

In water cooling, the liquid is potentially harmful to electronics and thus flows through a sealed loop isolated from the heat source. A watertight water block is used to indirectly transfer the heat from the heat source to the working fluid.

In immersion cooling, however, heat is transferred directly away from the heat source using the working fluid. With immersion cooling, the working fluid must be non-conductive, which tend to be within four families of fluids:

- de-ionized water

- mineral oil

- fluorocarbon-based fluids

- synthetic fluids

A wide variety of fluids exist for the purpose of immersion cooling, with the most suitable being transformer oils and other electrical cooling oils. Non-purpose oils, including cooking, motor, and silicone oils have also been successfully used to cool computer servers.

Submer SmartCoolant liquid – our very own immersion cooling fluid solution – is a dielectric, synthetic, proprietary fluid, is certified as 100% non-hazardous and biodegradable according to OECD 301. The properties of the SmartCoolant fluid allow for a higher heat transfer performance than air – learn more about it in our ebook here!

What Different Types of Immersion Cooling Are There?

1. Single-Phase Immersion Cooling

Single-phase coolant never changes state; it doesn’t boil nor freeze and always remains in its liquid form. The coolant is pumped into a heat exchanger where the heat is then transferred to a cooler water circuit.

This technique uses open baths as there is little to no risk of the coolant evaporating.

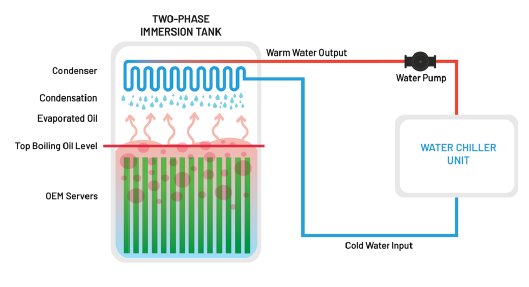

2. Two-Phase Immersion Cooling a.k.a. Evaporative Cooling/Flow Boiling

In two-phase cooling, the working fluid can exist in either a liquid or gas state. This method takes advantage of a concept known as latent heat, where thermal energy is required to change the state of a fluid. The working fluid is cooled when it reaches its boiling point and will remain at this saturation temperature. Energy is transferred from the heat source into the working fluid, causing a portion of it to boil off into a gas. Once this occurs, the gas rises above the fluid pool where it is then condensed back to saturation temperature. This causes the fluid to drop back into the fluid pool.

This cooling method requires semi-open baths, meaning that the system is sealed during operation the coolant evaporating.

Two-phase coolants are also extremely expensive and the effect of the vapor on the bath operators is still largely unknown.

In two-phase or even some single-phase immersion cooling fluids, evaporation can pose problems. The fluid may need regularly refilled or sealed inside the bath’s enclosure.

At Submer, we use our very own SmartCoolant: a special synthetic dielectric coolant, specifically designed for single-phase immersion cooling. SmartCoolant comes with the unique advantage of being entirely biodegradable and its harmony with a 22U and a 45U open-bath system is designed for easy day-to-day operation in any datacenter. Get in touch with us to find out more today!